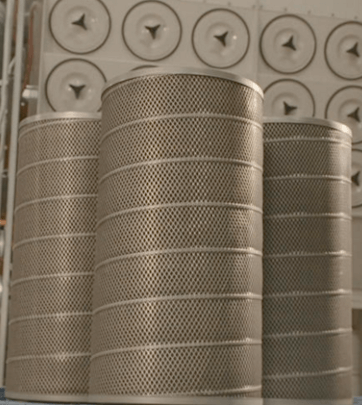

Countless industries depend on dust collector cartridge filters to clean the air in their plants, facilities, and workshops. Dust collector filters are built to withstand high-volume dust loads and feature a pleated design to provide more surface area. Because their design allows air to flow through them easily, dust collector filters are highly effective at capturing dust and other airborne contaminants.

The most important thing to remember about dust collector cartridge filters is to change them on-time. Changing dust collector filters regularly will prevent dust and other contaminants from accumulating in the airstream and decreasing the filter efficiency. Keeping up-to-date on dust collector maintenance and filter changes maximizes filter life, compressed air, and energy savings.

So, how do you know when it’s time? Here are five common signs!

1. Changes in Air Quality

When dust collector cartridge filters go unchanged they become worn and can develop microtears in the filter media. Once filter media becomes torn, the filters are less effective at capturing dust and other harmful air contaminants. If your facility vents filtered air back into the building, there will be an obvious difference in the air quality.

Changing dust collector filters regularly ensures that regulations are met and prevents the risk of poor filter performance.

2. Differential Pressure

Differential pressure or DP, measures the difference in pressure between the clean and dirty side of a dust collector. When dust builds up on cartridge filters, it makes it harder for air to pass through and creates unequal pressure that makes the DP higher.

Machine operators and maintenance technicians should be kept aware of the dust collector manufacturer’s recommended differential pressure to prevent excessive run time and filter failure.

3. Overextended Filter Lifespans

When dust collectors are equipped with technology that measures filter performance and filter changes, it’s almost impossible to forget when it’s time for replacements. When dust collectors don’t feature this type of technology, machine operators and maintenance techs have to rely on manufacturer-recommended replacement specs.

Replacing dust collector filters regularly helps the entire dust collection system run at its most efficient by improving air quality, keeping maintenance costs down, and meeting regulations.

4. Using Incompatible Filters

In order for filters to be effective, they must meet the specifications of the dust collection system and the demands of the application – this means filters are the right dimensions and are made of the right filter media.

If you need assistance determining or sizing the proper dust collector filters, Contact us, and our team will provide you with a free quote!

5. Regular Wear & Tear

Regularly inspect the clean-air side of the dust collector for leaks and the cartridge filters for tears. Don’t forget to clean the DP gauge, tighten loose gaskets, replace end caps, etc.

Monitoring dust collectors for wear and tear helps prevent the risk of equipment malfunction and production loss.